Note: Alex has changed designs since this article. View his website here: https://www.spicershollow.com.au

HEBEL HIVES

Article and Photos by Alex Derrick

Standard Box Dimensions

Internal – 180mm x 180mm square, 154 mm high

External footprint – 280 mm square x 204 mm high – 254 mm high with lid

Wall thickness – 50 mm AAC ( autoclaved aerated concrete)

Volume -5.0 lt

Weight – 12.5 kg complete

Suitable for TH & TC

Fitted lid with 25mm aluminium angle. Viewing panel and lino overlay included

3 coats of exterior white acrylic paint.

Why Hebel ?

As a carpenter I’ve been exposed to hebel within the construction industry. I also know a lot about timber and how it behaves, particularly in exposed situations. When I got into native bees it was advised that 40-50 mm wall thickness in a box was pretty much mandatory. I’d also lost my first hive to pests. A messy split that left a weak and small colony open to attack. I vowed not to split again after that and priced up materials to make one piece, eduction only boxes.

Quality 200×50 timber was too expensive at around $35 per mt. Then there is the movement and shrinkage factor. All timber changes dimensionally when drying or with changes in humidity with the seasons. It can’t be stopped. The bigger the section of timber, the more the movement. Even kiln dried timber will move. Thus gaps become entry ways for pests and water. So even a one piece timber box will open up eventually. The timber will also cup. So a once flat fitting lid will no longer be flat, nor will the walls . So I started playing around with hebel. It comes in a range of sizes but I use 600x200x50 blocks. They are very cheap, easily worked and easily glued. I tried a variety of adhesives and all of them proved to be stronger than the hebel so I chose a non toxic, water based acrylic sealant which is very cost effective. The hives are very easy to put together but there is a definite process to follow in order to achieve the final result. I guess I’ve been experimenting with hebel for about a year and I’ve finally settled on a standard design that caters for both TC & TH. A honey super is under development at the moment. I initially started developing a vertical splitting hive as I believe that if one must split, vertical is the way to go. Generally much less mess and an even age spread of the brood. I discontinued pursuing this line though.

Pros – Great insulation, thermal mass, rot proof, termite proof, weather proof, fire tolerant and one of the most pest resistant boxes on the market

Cons – Dusty to cut (wear mask and have dust extraction), requires sealing on the outside. Some see the weight as a disadvantage but there are no real negatives.

Bees – I have 4 hebel hives currently under eduction, 2 are nearly ready to separate. I will be fitting up another 2 shortly. The bees seem to accept the hebel readily seem to relish in the thermal mass slow release of the stored heat in winter. I have 2 with TH and 2 with TC (soon to be 4 TC)

Thermal mass – Thermal mass is something that can work for and against hives. Think of a concrete wall. In summer sun the wall slowly heats up and then radiates heat all night. In the shade of winter the wall remains cool all day and all night. Using hebel and reversing the positioning to Full winter sun and Full summer shade, the hive stores heat during the day in winter and releases it slowly overnight while in summer the shaded thermal mass very slowly absorbs the heat of the day, smoothing the rate of heat gain inside the hive. It is the rapid spike in heat that kills bees. So thermal mass is a very good tool to have as a native bee keeper, provided it is used properly. Hebel gives me that tool to use whereas timber does not. The excellent insulation properties of hebel compliment its thermal mass attributes.

Hive clamps

I designed the hive clamps to provide a stable platform for any box that measures between 190 mm and 340mm. For example, a standard OATH box could be mounted either across or lengthways in the hive clamp. There are a range of lower mounting sections for different applications.

There are currently 3 different lower mount options.

- Star picket

- Post mount

- Pedestal mount.

Variations on the post mount and pedestal mount are made as requested. See Australian Native Bee Network or Australian Native Bee Facebook pages for video footage.

Hive clamp with post mount. Video footage on ANBN & ANB Facebook pages

Early vertical splitting Hebel hive. 8.0lt volume. Stainless Steel support wires. One is

currently under eduction and is called the BHH ( Big Hebel Hive). Follow its progress on

ANBN & ANB Facebook pages.

5 custom sized boxes for a customer. 4.5 lt volume

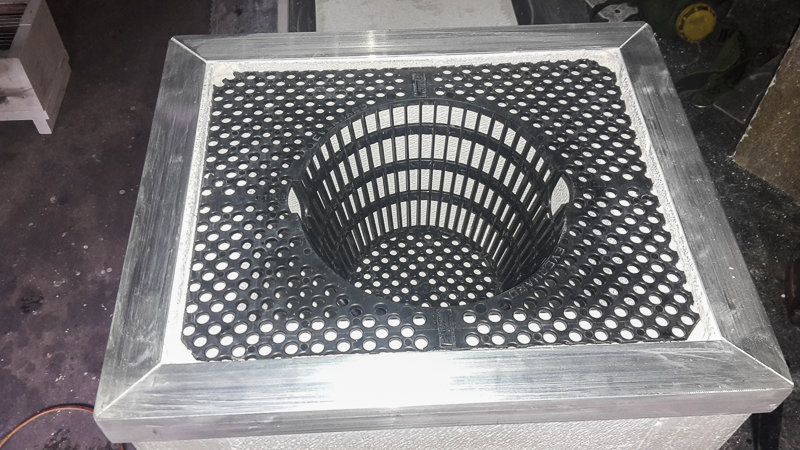

The LHH ( little hebel hive) with experimental brood basket. Currently under eduction

and nearly ready to separate. See its progress on ANBN & ANB Facebook pages

My standard box. Comes with the two caps for the entrances, viewing panel and lino

overlay (which goes on top of the viewing panel before the lid is put on) The eduction

fittings are not included.

Standard box, hive clamp and custom bottom mount. Eduction set up in the bush.

Contact

For the moment people can contact me either directly through Facebook messenger or through Australian Native Bee Network or Australian Native Bee Facebook pages. Or via email. I will be modifying my business website to include pages on Bee related products and services as well as starting a new Facebook page.

Website: https://www.spicershollow.com.au