This article is about moisture content and wood only, not humidity conditions for bee colonies.

Woodworkers will want their timber to be well dried before making furniture. They’ll aim for a Moisture Content (MC) around 6 – 10% in the timber. A live standing tree would be considered to be 100% moisture content.

Wood will change in moisture content depending on the Relative Humidity. It can dry out but can also increase in moisture content and change shape or expand and retract.

This is where making native bee hives could become complicated. The Relative Humidity inside a normal native bee hive box could be 70 – 90%.

If you start out with wood that is 8% MC, once you make the box and put bees in to it, the moisture content of the wood might increase to around 15%. 15% MC is an acceptable range for wood to be when considering mould and rot though this can be a bit frustrating when your beautifully finished box develops some slight imperfections. Some panels could expand, some could shrink and split depending on how the box is constructed.

It doesn’t matter if the wood has been kiln dried, or you have had it stacked up for 20 years, it will always change moisture content depending on it’s surrounding relative humidity. If you leave the wood out in your garage or shed then it will probably be around 10-13% MC depending on the surrounding environment.

It’s very unlikely you can actually seal the wood to stop any moisture. Any sealing will only slow the process down.

Another thing to consider is adding better ventilation, possibly more vent holes. If the bees don’t like it they will seal the holes.

Relative Humidity vs Moisture Content of the surrounding wood

From an article on the “thisiscarpentry.com” website, they suggest the following figures. The MC of wood will be 20% or 1/5th of the Relative Humidity percentage.

- 0% RH = 0% MC of the surrounding wood

- 25% = 5%

- 50% = 10%

- 75% = 15%

- 99% = 23-30%

How do we measure Moisture Content?

The only way to accurately measure MC is by using an electronic moisture meter. These can range from $30 to hundreds. Do you really need one? No. If you’re interested in that kind of thing and do plenty of wood work then yeah grab one. There’s ones that have two spikes that you press in to the wood and they measure the conductivity between the points, or there’s more expensive ones that just sit on the wood and transmit and receive magic signals through the wood. These measure the wood density so you have to know the weight in cubic metres of the wood. You select the weight of the wood in the meters setttings and then test the wood and a percentage reading will display.

Density weight examples for wood we might use in Australia

- Hoop Pine 560 kg/m3

- White Cypress 675 kgm3

- Western Red Cedar 380 kg/m3

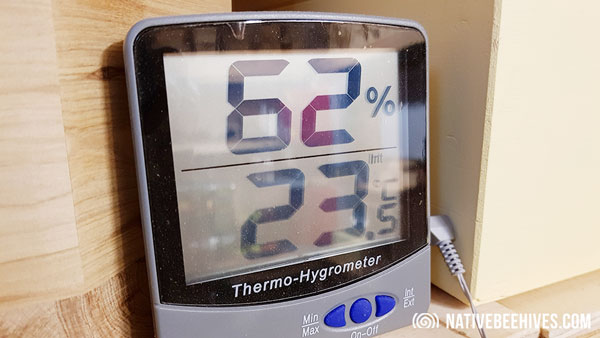

You could also use a Hygrometer (Relative Humidity) and work backwards and predict the MC of wood. If the RH is 80% then the MC of the wood might be around 15 – 16%.

Keep in mind that the Relative Humidity is changing daily and the moisture content of the wood doesn’t change that fast, it’s a very slow process. You may need months for the wood to level out in moisture content.

Hygrometer – Relative Humidity

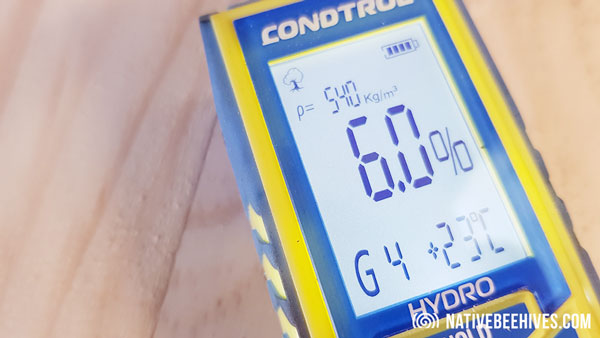

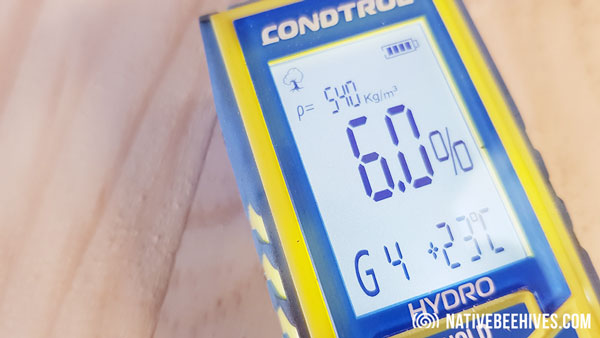

Pine – 6% Moisture Content. Set at the closest setting of 540 kgm3

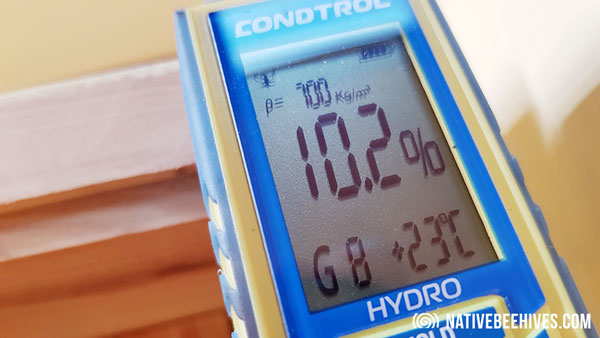

Cypress – 10%. Set at the closest setting of 700 kgm3

===========================================

Plastic Vs Wood for Condensation

Condensation happens when the moisture in the air contacts a cold surface and returns to liquid. This is more likely to happen if a hive box is half empty and there’s more air space inside, for example after a recent split. You might see some dried liquid stains outside the bee hive entrance as the bees spit out the moisture. This can happen in both plastic and wood hive boxes. Wood may have the ability to absorb moisture but it wont be long before all surfaces inside the box are covered in resin, so the woods ability to absorb moisture will greatly decline anyway and will only be able to absorb moisture over a very long period. Wood wont make a difference for day to day moisture changes. Box makers might add extra holes or “vents” in the box to help the box breathe.

======================

Quote from the link – http://www.rlcengineering.com/wmc.htm

Wood Moisture Content Scale’s Meanings: (WMC)

Below 12% – Readings in this range are common to kiln or oven dried woods and furniture grades of wood, and represent dry conditions. Most interior wood is in this range.

12% – 16% – Readings in this range are common to lumber during construction, air dried lumber and “healthy” residential substructures (beneath first floor in crawl spaces). These are typical readings for exterior wood.

16% – 20% – Readings in this range indicate a possible elevated level of wood moisture. Such readings should alert the homeowner to look for a source of excess moisture. The excess moisture source should be corrected if found.

20% – 28% – Readings in this range indicate that conditions are border-line for decay. Surface molds may develop. The excess moisture source should be corrected immediately, and monitored until the WMC returns to the 12-16 range.

28% and above – Readings in this range are often accompanied by decay damage. Substructures with WMC in this range may show decay or rot in floor joist, sills, and subflooring. Repair is often required when WMC readings are in this range.

Wood moisture content between 0% and about 28% is dependent upon the relative humidity (RH) of the air. As the air’s RH increases, so does the moisture content of any wood exposed to the air. Wood exposed to air with a RH of about 90% will reach a Wood Moisture Content of about 20%. Above 90% RH or 20% WMC, mold can grow on the wood.

Decay fungi need liquid water to grow. Once wood is dried below about 28% WMC, water is not available to support decay, unless the wood is exposed to liquid water. This water may come from condensation, roof leaks, plumbing leaks, or contact with the soil. If decay or WMC readings over 28% are present, find and fix the sources of liquid water quickly.

===========================================

Quote from the thisiscarpentry.com article:

In-service high humidity issues

Typically, high humidity (constant levels above 60%) is not an issue. But if you find yourself working on a project that includes a room with a spa, heated pool, or damp crawl space, proceed with serious caution—85% RH means an 18% EMC. A 12-in. wide piece of birch installed at 8% MC in such a room will swell in width over 3/8 in. Letting your material acclimate to the high MC levels before installing is one approach, but keep in mind that if there is ever a period where the pool is drained for a significant time, and the humidity drops to typical levels, the trim material will experience severe shrinkage. A carefully-worded disclaimer regarding wood movement would seem to be in order.

==========================================

Do we need to change anything that we’re currently doing?

I don’t think we need to change anything, just keep making boxes but think about how moisture can affect the kind of wood we use and understand that once you have a bee colony inside the box it may change shape causing imperfections, cracks, gaps and all wood should be monitored over time to check any negative effects caused by ongoing high moisture like mould and rot.

- If you’re getting mould and rotting timber then the moisture content must be too high and what’s the cause. It could be the wood you’re using is more susceptible, or excess outside water is getting in to the gaps. The boxes may need better protection from the outside elements like a better roof.

- Nails or screws can provide an entry point for moisture right in to the wood. Try to use stainless or coated screws and then cover or seal them. Normal steel rusts and can act as a wick drawing more moisture in to the center of the wood.

- Does condensation form on steel brood supports and that becomes a transfer point for water to the wood? We might need more research on that.

========================================================================

More articles for your reading

https://www.ncbi.nlm.nih.gov/pubmed/26994173

http://www.jyi.org/issue/stinglessbees/

https://www.wagnermeters.com/what-is-equilibrium-moisture-content/

http://www.delmhorst.com/blog/how-does-the-relative-humidity-affect-the-quality-of-wood

https://www.daf.qld.gov.au/forestry/using-wood-and-its-benefits/wood-properties-of-timber-trees

http://www.woodproducts.fi/content/moisture-properties-wood

This article has some great info about moisture content in wood if you have some time

==============================================================

Vapour Pressure

Is Vapour Pressure a contributor here? This does my head in 🙂

https://en.wikipedia.org/wiki/Vapour_pressure_of_water

==============================================================

I’ll add and/or modify this article with more info over time.

Is there something you’d like to add or change here? Send me an email: https://www.nativebeehives.com/contact/